Welcome to the future of mobility, where innovation meets responsibility and progress is powered by purpose.

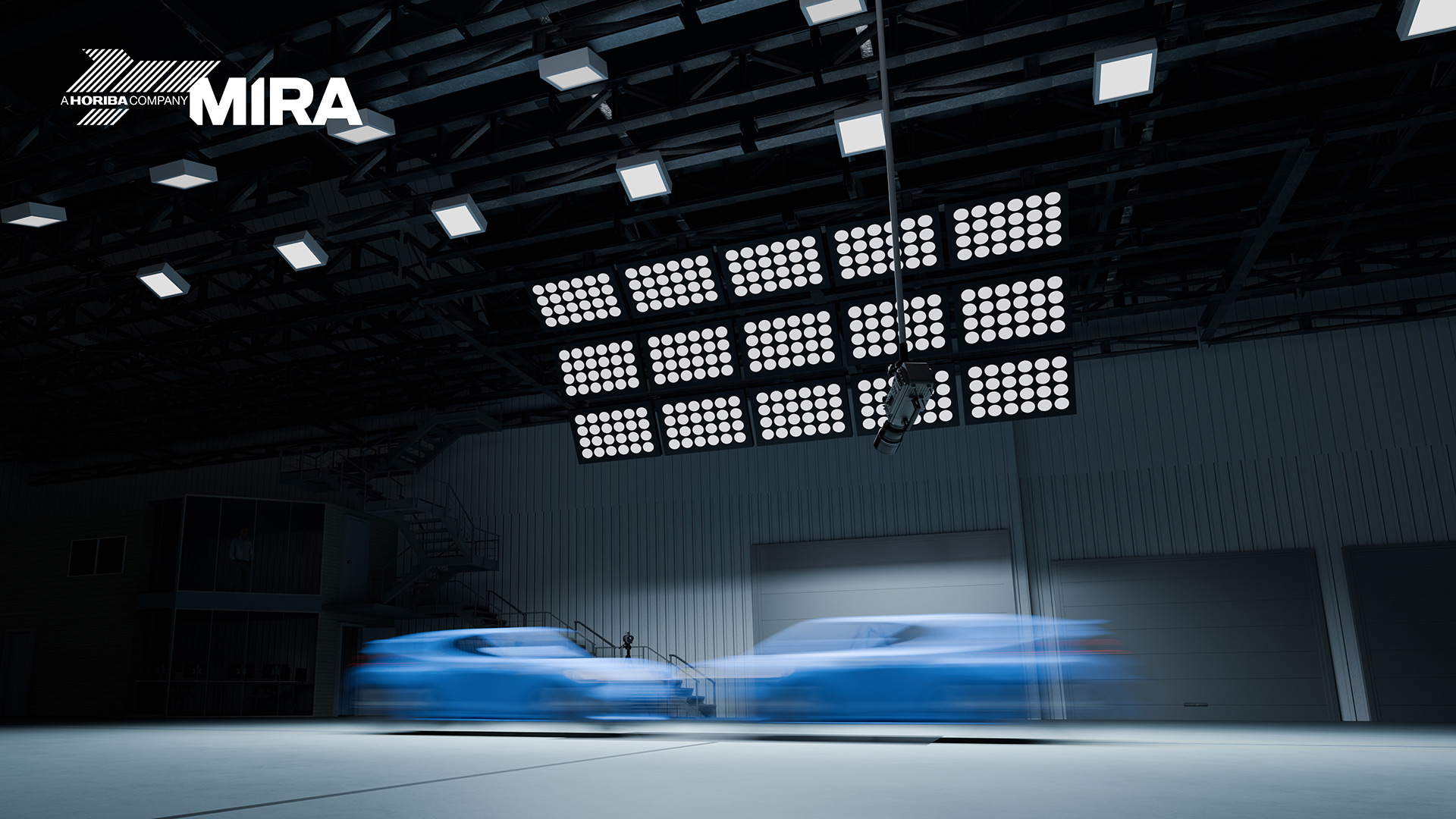

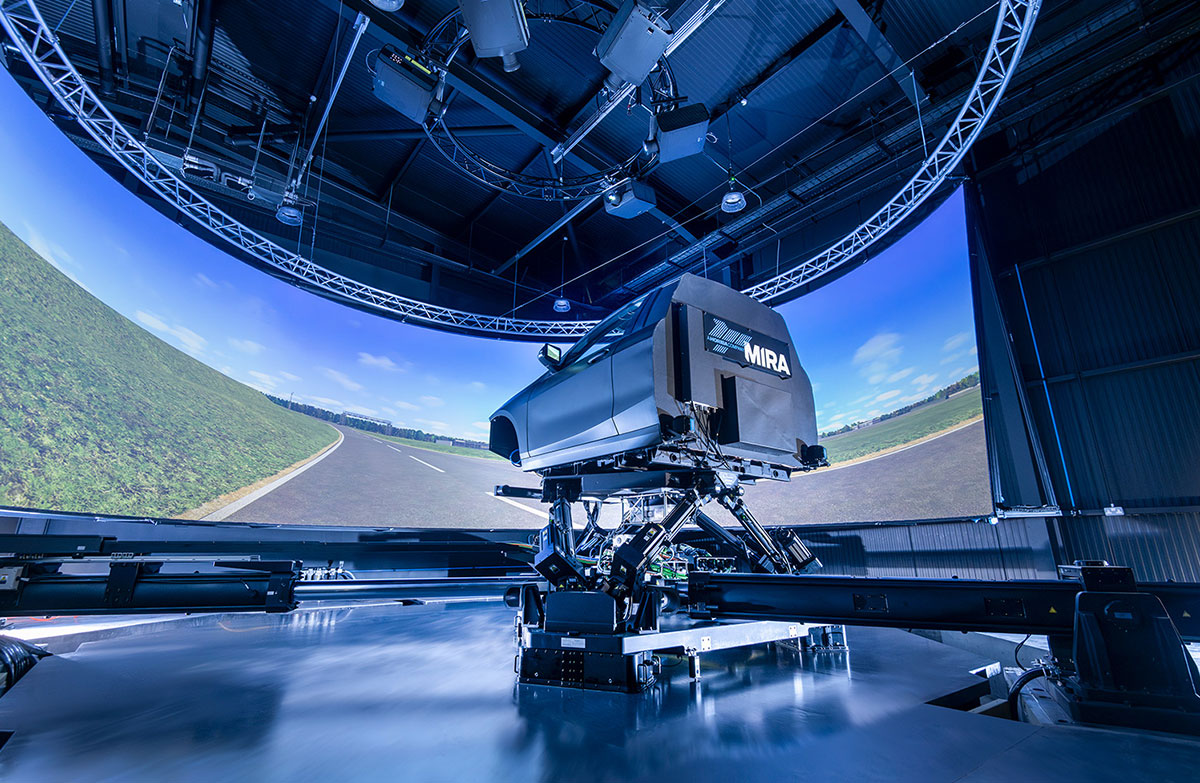

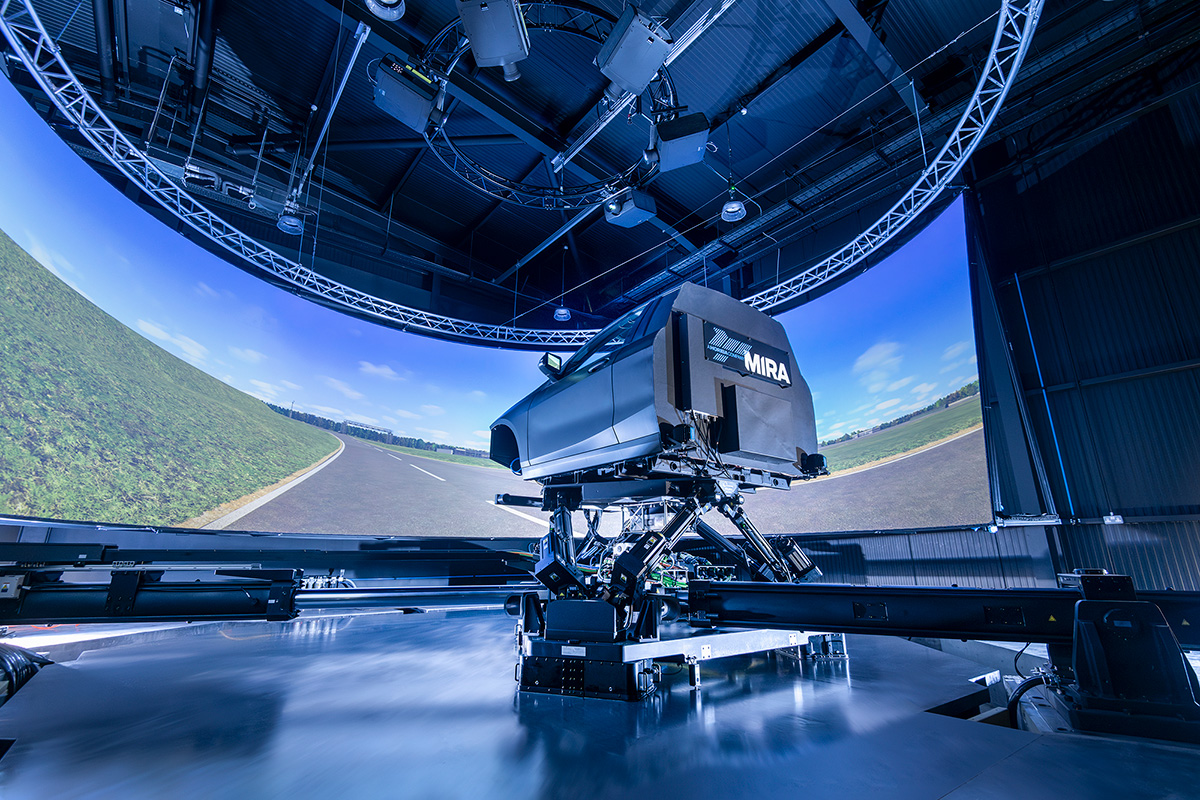

With nearly 80 years of automotive engineering innovation to our name, we’re stepping boldly into the future. We’ve redefined our focus, aligned our engineering capabilities, and invested in pioneering facilities.

We’re enabling auto makers to engineer vehicles virtually, significantly reducing the reliance on carbon-intensive prototypes.

What We Do

Developing the best talent via stimulating careers pathways is crucial to our success.

Our facilities and engineering capabilities continue to evolve, so to do our teams of dedicated individuals who contribute in so many varied and crucial ways.

We believe that strong investment in developing suitable candidates for future careers is essential, so we’re always looking at making available as many exciting opportunities as we can.